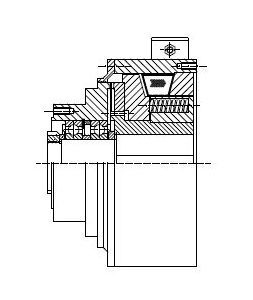

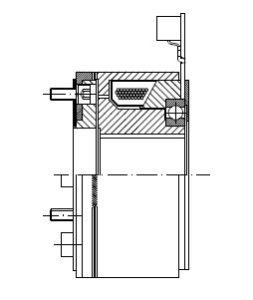

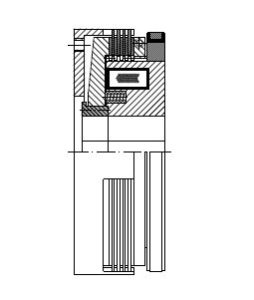

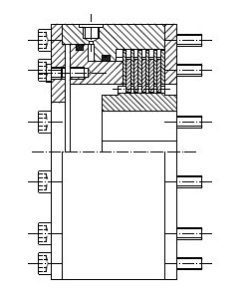

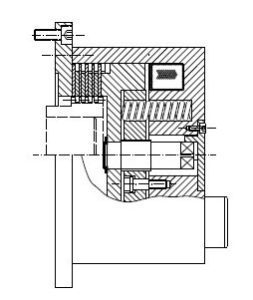

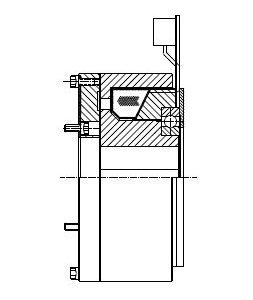

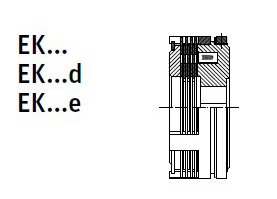

Description

• Clutch for positive-locking torque transmission with splined guide

• For dry- and oil-operations

• Tooth design

1) disengage under torque load

2) high torque

• Maintenance-free

• Accessory: position indicator

• Torque: 25-5,000 Nm

• Standard voltage 24V DC; other versions on request

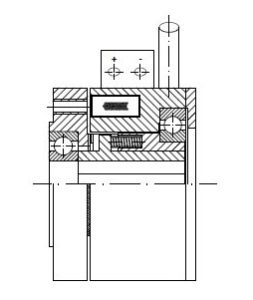

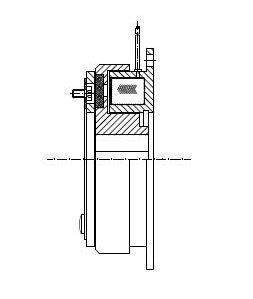

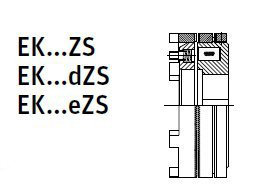

Standard Features

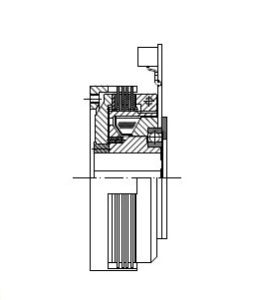

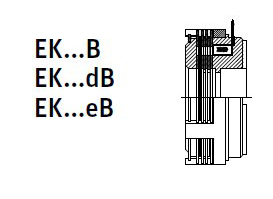

Description

• Clutch for positive-locking torque transmission with splined guide

• For dry- and oil-operations

• Tooth design

1) disengage under torque load

2) high torque

• Maintenance-free

• Accessory: position indicator

• Torque: 25-5,000 Nm

• Standard voltage 24V DC; other versions on request

Standard Features

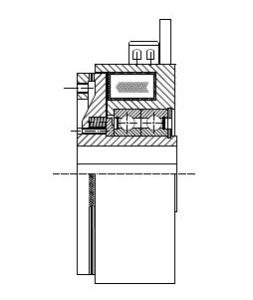

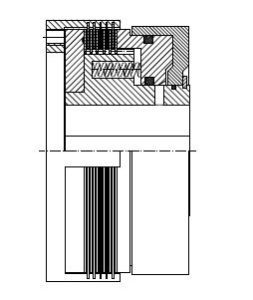

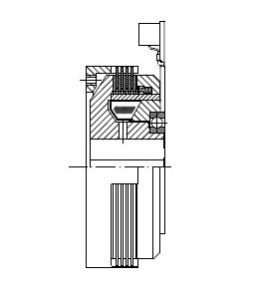

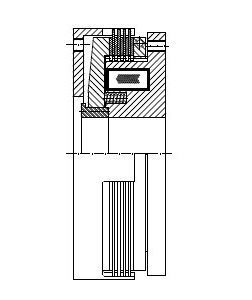

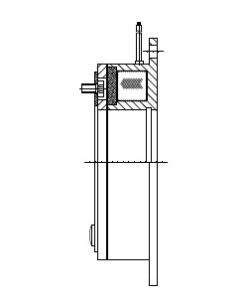

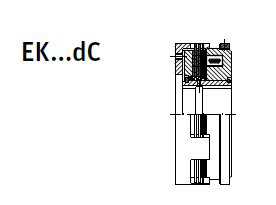

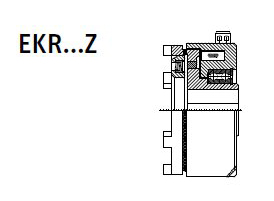

Description

• Clutch designed for fitting into the gear boxes of machines with high torque load, construction machinery and transport equipment • Designed with air-pressure supply through the shaft

• Maintenance-free

• Torque: 80-2,500 Nm

• Standard operation pressure 6 bar; other versions on request

Standard Features

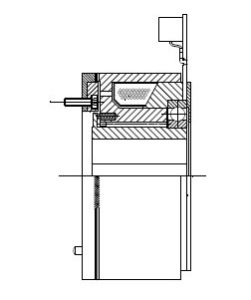

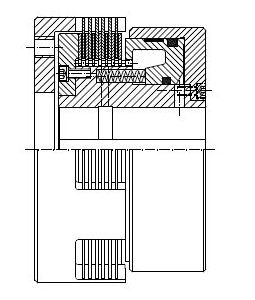

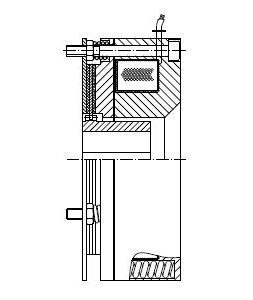

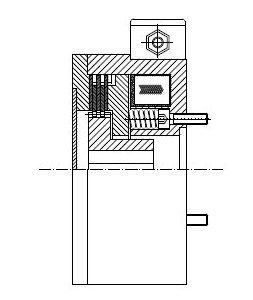

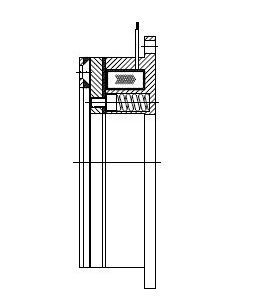

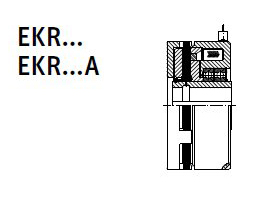

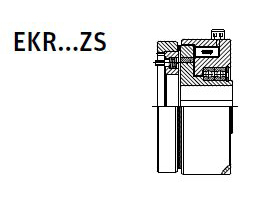

Description

• Clutch designed for fitting into the gear boxes of machines with high torque load, construction machinery and transport equipment

• Designed with pressurized oil supply through the shaft

• Maintenance-free

• Torque: 160-11,000 Nm

• Standard operation pressure 24 bar; other versions on request

Standard Features

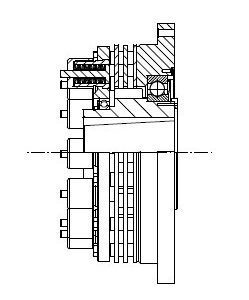

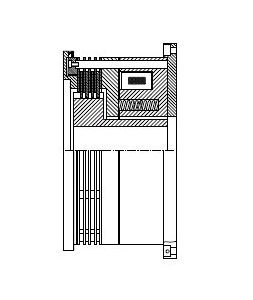

Description

• Clutch for adjustable torque-limit of startup and overload applications

• Safety clutch

• Clutch operation functions as overload clutch to protect machinery equipment or handling and lifting devices against damage from collision or other unwanted overload situations.

• Torque: 10-85,000 Nm

Standard Features

Description

• Organic discs are a modern and efficient variant of friction discs. They have a higher overall coefficient of friction and therefore higher transmittable torque.

• By modifying the structure of the friction fibres and the fillers, the operating parameters can be variegated whereby an accurate adjustment on operating parameters and application is possible.

Standard Features

Description

• Sintered discs are approved friction-partners for steel discs and can be manufactured with different groove forms such as “Sunburst”, “Waver” or “Spiral”.

• Through adjustments of the core material quality and mixture of the sinter material, a wide range of different applications can be customized.

Standard Features

Description

• Steel discs are available in different designs of profiles, toothings or surface groovings.

• The raw material and the hardness are selected individually in regard to the application.

• The dimensioning is absolutely flexible, considering the existing construction space, on the basis of the required operating parameters.

Standard Features